Laser cutting is one of the most important application technologies in the laser processing industry. Technological workers continue to explore the laser cutting processing technology and promote the continuous development of laser cutting technology. At the same time, fiber laser cutter companies need to step out of price competition and practice internal skills. Because of their many advantages, they have been widely used in automobile, rolling stock manufacturing, aviation, chemical industry, light industry, electrical appliances and electronics, petroleum and metallurgy, etc.

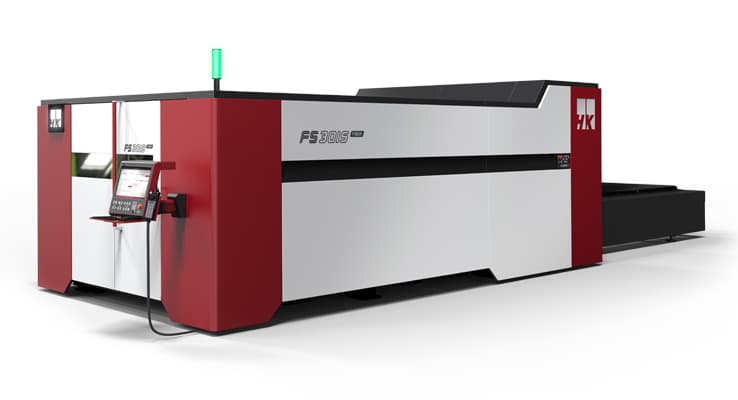

Highly configurable and expandable, the RAPID keeps everything moving quickly and efficiently well into the future.